Reaction calorimeter

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages)

|

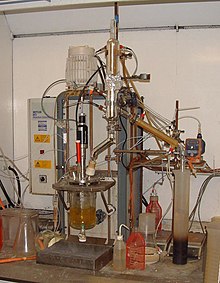

A reaction calorimeter is a calorimeter that measures the amount of energy released (in exothermic reactions) or absorbed (in endothermic reactions) by a chemical reaction. It does this by measuring the total change in temperature of an exact amount of water in a vessel.

Methods

[edit]Heat flow calorimetry

[edit]Heat flow calorimetry measures the heat flowing across the reactor wall and quantifies this in relation to other energy flows within the reactor.

where:

- → process heating (or cooling) power (W)

- → overall heat transfer coefficient (W/(m2K))

- → heat transfer area (m2)

- → process temperature (K)

- → jacket temperature (K)

Heat flow calorimetry allows the user to measure heat while the process temperature remains under control. While the driving force Tr − Tj is measured with a relatively high resolution, the overall heat transfer coefficient U or the calibration factor UA is determined by calibration before and after the reaction takes place. These factors are affected by the product composition, process temperature, agitation rate, viscosity, and liquid level.[1]

Heat balance calorimetry

[edit]In heat balance calorimetry, the cooling/heating jacket controls the temperature of the process. Heat is measured by monitoring the heat gained or lost by the heat transfer fluid.

where:

- → is the process heating (or cooling) power (W)

- → is the mass flow of heat transfer fluid (kg/s)

- → is the specific heat of heat transfer fluid (J/(kg K))

- → is the inlet temperature of heat transfer fluid (K)

- → is the outlet temperature of heat transfer fluid (K)

Heat balance calorimetry is considered an effective method for measuring heat, as it involves quantifying the heat entering and leaving the system through the heating/cooling jacket using the heat transfer fluid, whose properties are well known.

This method effectively measures heat loss or gain, circumventing many calibration issues associated with heat flow and power compensation calorimetry. However, it is less effective in traditional batch vessels, where significant heat shifts in the cooling/heating jacket can obscure the process's heat signal.[2]

Power compensation calorimetry

[edit]Power compensation calorimetry is a variation of the heat flow technique. This method utilizes a cooling jacket operating at constant flow and temperature. The process temperature is regulated by adjusting the power of an electrical heater. At the start of the experiment, the electrical heat and cooling power are balanced. As the process's heat load changes, the electrical power is adjusted to maintain the desired process temperature.[3] The heat liberated or absorbed by the process is determined from the difference between the initial electrical power and the electrical power required at the time of measurement. While power compensation calorimetry requires less preparation than heat flow calorimetry, it faces similar limitations. Changes in product composition, liquid level, process temperature, agitation, or viscosity can impact the instrument's calibration. Additionally, the presence of an electrical heating element is not optimal for process operations. Another limitation of this method is that the maximum heat it can measure is equal to the initial electrical power applied to the heater.[4]

where:

- is the current supplied to the heater

- is the voltage supplied to the heater

- is the current supplied to the heater at equilibrium (assuming constant voltage / resistance)

Constant flux calorimetry

[edit]

Constant flux heating and cooling jackets use variable geometry cooling jackets and can operate with cooling jackets at a substantially constant temperature. These reaction calorimeters are simpler to use and are much more tolerant of changes in the process conditions.[5]

Constant flux calorimetry is an advanced temperature control mechanism used to generate accurate calorimetry. It operates by controlling the jacket area of a laboratory reactor while maintaining a constant inlet temperature of the thermal fluid. This method allows for precise temperature control, even during strongly exothermic or endothermic events, as additional cooling can be achieved by increasing the area over which heat is exchanged.

This system is generally more accurate than heat balance calorimetry, as changes in the delta temperature (Tout - Tin) are magnified by keeping the fluid flow as low as possible.

One of the main advantages of constant flux calorimetry is the ability to dynamically measure heat transfer coefficient (U). According to the heat balance equation:

From the heat flow equation that

These equations can be rearranged to:

This allows for the monitoring of U as a function of time.

Instrumentation

[edit]

In traditional heat flow calorimeters, one reactant is added continuously in small amounts, similar to a semi-batch process, to achieve complete conversion of the reaction. Unlike in a tubular reactor, this approach results in longer residence times, different substance concentrations, and flatter temperature profiles. Consequently, the selectivity of less well-defined reactions can be affected, potentially leading to the formation of by-products or secondary products. These by-products can alter the measured heat of reaction as different chemical bonds are formed. The amount of by-product or secondary product can be determined by calculating the yield of the desired product.

A continuous reaction calorimeter is a similar instrument used to obtain thermodynamic information on continuous processes in tubular reactors. It can record an axial temperature profile along the tubular reactor, allowing the determination of the specific heat of reaction through heat balances and segmental dynamic parameters. The system typically includes a tubular reactor, dosing systems, preheaters, temperature sensors, and flow meters.

If the heat of reaction measured in the heat flow calorimeter (HFC) differs from that measured in a plug flow reactor (PFR) calorimeter, it is likely that side reactions have occurred. These discrepancies may arise due to differences in temperatures and residence times. The total measured heat (Qr) comprises partially overlapped reaction enthalpies (ΔHr) of both main and side reactions, depending on their degrees of conversion (U).

Continuous reaction calorimeters offer significant advantages in the study of continuous processes, particularly in industrial applications where consistent and reproducible reaction conditions are critical. These instruments can provide detailed insights into the thermodynamics and kinetics of reactions under steady-state conditions. The use of precise dosing systems ensures accurate control over reactant flow rates, while preheaters can stabilize the temperature of incoming reactants, minimizing temperature fluctuations that could affect the reaction rate and selectivity.

Moreover, advanced temperature sensors and flow meters enable real-time monitoring and control of the process parameters, facilitating the optimization of reaction conditions. By recording axial temperature profiles, researchers can identify temperature gradients within the reactor, which can inform adjustments to improve heat transfer efficiency and reaction uniformity. This capability is particularly important in scaling up reactions from laboratory to industrial scale, where maintaining consistent product quality and yield is essential.

Continuous reaction calorimeters also allow for the study of reaction mechanisms and the identification of intermediate species. By analyzing the heat flow data in conjunction with other analytical techniques, such as spectroscopy or chromatography, researchers can gain a comprehensive understanding of the reaction pathways and the factors influencing selectivity and yield. This information is invaluable for developing efficient and sustainable chemical processes, reducing waste, and minimizing energy consumption.

See also

[edit]References

[edit]- ^ reserved, Mettler-Toledo International Inc all rights. "Reaction Calorimeters". www.mt.com. Retrieved 2024-05-06.

- ^ Kossoy, Arcady (September 2023). "Reaction calorimetry: Main types, simple theory, and application for kinetic study—A review". Process Safety Progress. 42 (3): 417–429. doi:10.1002/prs.12452. ISSN 1066-8527.

- ^ Toubes-Rodrigo, Mario (March 13, 2024). "Calorimetry: Heat flow versus power compensations methods". H.E.L. Group.

- ^ Cooksley, Katherine. "Calorimetry: heat flow versus power compensations methods". H.E.L Group. Retrieved 2024-06-02.

- ^ "Handbook of Thermal Analysis and Calorimetry", Recent Advances, Techniques and Applications, vol. 5, Elsevier, pp. ii, 2008, doi:10.1016/s1573-4374(13)60004-7, ISBN 978-0-444-53123-0, retrieved 2024-05-28

- Moser, Marlies; Georg, Alain G.; Steinemann, Finn L.; Rütti, David P.; Meier, Daniel M. (September 2021). "Continuous milli-scale reaction calorimeter for direct scale-up of flow chemistry". Journal of Flow Chemistry. 11 (3): 691–699. doi:10.1007/s41981-021-00204-y. hdl:11475/23441. ISSN 2062-249X.

- Mortzfeld, Frederik; Polenk, Jutta; Guelat, Bertrand; Venturoni, Francesco; Schenkel, Berthold; Filipponi, Paolo (2020-10-16). "Reaction Calorimetry in Continuous Flow Mode: A New Approach for the Thermal Characterization of High Energetic and Fast Reactions". Organic Process Research & Development. 24 (10): 2004–2016. doi:10.1021/acs.oprd.0c00117. ISSN 1083-6160.