Rake angle

Appearance

This section needs additional citations for verification. (November 2019) |

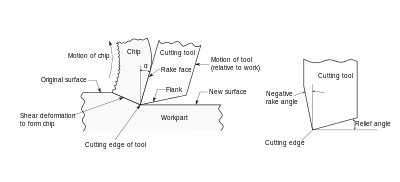

In machining, the rake angle is a parameter used in various cutting processes, describing the angle of the cutting face relative to the workpiece. There are three types of rake angles: positive, zero or neutral, and negative.

- Positive rake: A tool has a positive rake when the face of the cutting tool slopes away from the cutting edge at inner side.

- Zero rake: A tool has a zero (or neutral) rake when the face of the cutting tool is perpendicular to the cutting edge at inner side.

- Negative rake: A tool has a negative rake angle when the face of the cutting tool slopes away from the cutting edge at outer side.

Positive rake angles generally:

- Make the tool more sharp and pointed. This reduces the strength of the tool, as the small included angle in the tip may cause it to chip away.

- Reduce cutting forces and power requirements.

- Helps in the formation of continuous chips in ductile materials.

- Can help avoid the formation of a built-up edge.

Negative rake angles generally:

- Increase the strength of the cutting edge. The tool is more blunt.

- Increases the cutting force.

- Increases the power required for a cut.

- Can increase friction, resulting in higher temperatures.

- Can improve surface finish.

Zero rake angles:

- Easier to manufacture.

- Easier to resharpen.

- Less power and cutting forces than a negative raked tool.

- Chip will wear and 'crater' the rake face.[1]

Recommended rake angles

[edit]Recommended rake angles can vary depending on the material being cut, tool material, depth of cut, cutting speed, machine, setup and process. This table summarizes recommended rake angles for: single-point turning on a lathe, drilling, milling, and sawing.

| Material being cut | Turning Rake [2] | Drilling Rake [3] | Milling Rake [4] | Sawing Rake [5] |

|---|---|---|---|---|

| Aluminum | 12°-25° | 40° | 35° | 12°-25° |

| Brass | 3°-14° | 8° | 0° | 3°-14° |

| Bronze | 5°-14° | 0° | 5°-14° | |

| Cast Iron, Gray | 0°-6° | 0° | 5° | 3°-6° |

| Copper | 18°-25° | 16° | 18°-25° | |

| Polystyrene | 20°-25° | 20°-25° | ||

| PVC | 20°-25° | 20°-25° | ||

| Stainless Steel | 8°-10° | 8° | 8° | 8°-10° |

| Steel, Mild | 12°-14° | 20° | 8°-15° | 12°-14° |

| Titanium | 0°-4° | 0°-4° |

References

[edit]- ^ "Geometry of Single Point Cutting Tools". Scribd. Retrieved 23 November 2019.

- ^ "Rake Angle Versus Material". Thread Check Inc. Retrieved 24 November 2019.

- ^ "Machining & Metrology Unit - Handout (0102)". mmu.ic.polyu.edu.hk. Archived from the original on 2001-10-27.

- ^ "Grinding HSS lathe tools". Steve's Workshop. Retrieved 24 November 2019.

- ^ "Rake angle vs material chart" (PDF). Regal Cutting Tools. Retrieved 24 November 2019.