Оксид алюминия

| |

| |

| Имена | |

|---|---|

| Имя IUPAC

Оксид алюминия

| |

| Систематическое имя IUPAC

Алюминиевый (III) оксид | |

| Другие имена

Диаральный триоксид

| |

| Идентификаторы | |

3D model ( JSmol )

|

|

| Химический | |

| Chemspider | |

| Наркоман | |

| Echa Infocard | 100.014.265 |

| ЕС номер |

|

PubChem CID

|

|

| Rtecs номер |

|

| НЕКОТОРЫЙ | |

Comptox Dashboard ( EPA )

|

|

| Характеристики | |

| AL 2 O 3 | |

| Молярная масса | 101.960 g·mol −1 |

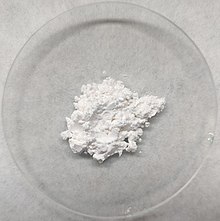

| Появление | белое твердое вещество |

| Запах | без запаха |

| Плотность | 3,987 г/см 3 |

| Точка плавления | 2,072 °C (3,762 °F; 2,345 K)[3] |

| Boiling point | 2,977 °C (5,391 °F; 3,250 K)[4] |

| insoluble | |

| Solubility | insoluble in all solvents |

| log P | 0.31860[1] |

| −37.0×10−6 cm3/mol | |

| Thermal conductivity | 30 W·m−1·K−1[2] |

Refractive index (nD)

|

nω = 1.768–1.772 nε = 1.760–1.763 Birefringence 0.008 |

| Structure | |

| Trigonal, hR30 | |

| R3c (No. 167) | |

a = 478.5 pm, c = 1299.1 pm

| |

| octahedral | |

| Thermochemistry | |

Std molar

entropy (S⦵298) |

50.92 J·mol−1·K−1[5] |

Std enthalpy of

formation (ΔfH⦵298) |

−1675.7 kJ/mol[5] |

| Pharmacology | |

| D10AX04 (WHO) | |

| Hazards | |

| GHS labelling: | |

| |

| NFPA 704 (fire diamond) | |

| Flash point | Non-flammable |

| NIOSH (US health exposure limits): | |

PEL (Permissible)

|

OSHA 15 mg/m3 (total dust) OSHA 5 mg/m3 (respirable fraction) ACGIH/TLV 10 mg/m3 |

REL (Recommended)

|

none[6] |

IDLH (Immediate danger)

|

N.D.[6] |

| Related compounds | |

Other anions

|

aluminium hydroxide aluminium sulfide aluminium selenide |

Other cations

|

boron trioxide gallium(III) oxide indium oxide thallium(III) oxide |

| Supplementary data page | |

| Aluminium oxide (data page) | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Оксид алюминия (или оксид алюминия (III) ) представляет собой соединение алюминия кислорода и химическое с химической формулой Al 2 O 3 . Это наиболее часто встречается из нескольких оксидов алюминия и специфически идентифицируется как оксид алюминия . Его обычно называют глинозмом , а также можно назвать алоксидом , алокситом или alundum в различных формах и приложениях. Он встречается естественным образом в своей кристаллической полиморфной фазе α-Al 2 O 3 в качестве минерального корунда , разновидности которых образуют драгоценные драгоценные камни рубин и сапфир . AL 2 O 3 используется для получения алюминиевого металла, как абразив из -за его твердости , и в качестве рефрактерного материала из -за высокой температуры плавления. [ 7 ]

Естественное явление

[ редактировать ]Corundum является наиболее распространенной природной кристаллической формой оксида алюминия. [ 8 ] Рубины и сапфиры являются качественными формами Corundum, которые обязаны их характерными цветами, чтобы отслеживать примеси. Рубины получают свой характерный глубокий красный цвет и их лазерные качества по следам хрома . Сапфиры бывают разных цветов, приведенных различными другими примесями, такими как железо и титан. Чрезвычайно редкая форма Δ происходит в виде минерального дельталумита. [ 9 ] [ 10 ]

История

[ редактировать ]Поле керамики оксида алюминия имеет долгую историю. Алюминиевые соли широко использовались в древней и средневековой алхимии . Несколько старых учебников охватывают историю области. [ 11 ] [ 12 ] Учебник 2019 года от Эндрю Руиса содержит подробную временную шкалу на История оксида алюминия с древних времен до 21 -го века. [ 13 ]

Характеристики

[ редактировать ]

AL 2 O 3 - электрический изолятор , но имеет относительно высокую теплопроводность ( 30 Вм −1 K −1 ) [ 2 ] для керамического материала. Оксид алюминия нерастворим в воде. В своей наиболее часто встречающейся кристаллической форме, называемой оксидом корунда или α-алюминия, его твердость делает его подходящим для использования в качестве абразивного и в качестве компонента режущих инструментов . [ 7 ]

Aluminium oxide is responsible for the resistance of metallic aluminium to weathering. Metallic aluminium is very reactive with atmospheric oxygen, and a thin passivation layer of aluminium oxide (4 nm thickness) forms on any exposed aluminium surface in a matter of hundreds of picoseconds.[better source needed][14] Этот слой защищает металл от дальнейшего окисления. Толщина и свойства этого оксидного слоя могут быть улучшены с помощью процесса, называемого анодизированием . Ряд сплавов , таких как алюминиевые бронзы , используют это свойство, включив долю алюминия в сплав для повышения коррозионной устойчивости. Оксид алюминия, генерируемый анодизированием, обычно является аморфным , но процессы окисления с помощью разрядов, такие как электролитическое окисление плазмы, приводят к значительной доле кристаллического оксида алюминия в покрытии, повышая его твердость .

Aluminium oxide was taken off the United States Environmental Protection Agency's chemicals lists in 1988. Aluminium oxide is on the EPA's Toxics Release Inventory list if it is a fibrous form.[15]

Amphoteric nature

[edit]Aluminium oxide is an amphoteric substance, meaning it can react with both acids and bases, such as hydrofluoric acid and sodium hydroxide, acting as an acid with a base and a base with an acid, neutralising the other and producing a salt.

- Al2O3 + 6 HF → 2 AlF3 + 3 H2O

- Al2O3 + 2 NaOH + 3 H2O → 2 NaAl(OH)4 (sodium aluminate)

Structure

[edit]

The most common form of crystalline aluminium oxide is known as corundum, which is the thermodynamically stable form.[16] The oxygen ions form a nearly hexagonal close-packed structure with the aluminium ions filling two-thirds of the octahedral interstices. Each Al3+ center is octahedral. In terms of its crystallography, corundum adopts a trigonal Bravais lattice with a space group of R3c (number 167 in the International Tables). The primitive cell contains two formula units of aluminium oxide.

Aluminium oxide also exists in other metastable phases, including the cubic γ and η phases, the monoclinic θ phase, the hexagonal χ phase, the orthorhombic κ phase and the δ phase that can be tetragonal or orthorhombic.[16][17] Each has a unique crystal structure and properties. Cubic γ-Al2O3 has important technical applications. The so-called β-Al2O3 proved to be NaAl11O17.[18]

Molten aluminium oxide near the melting temperature is roughly 2/3 tetrahedral (i.e. 2/3 of the Al are surrounded by 4 oxygen neighbors), and 1/3 5-coordinated, with very little (<5%) octahedral Al-O present.[19] Around 80% of the oxygen atoms are shared among three or more Al-O polyhedra, and the majority of inter-polyhedral connections are corner-sharing, with the remaining 10–20% being edge-sharing.[19] The breakdown of octahedra upon melting is accompanied by a relatively large volume increase (~33%), the density of the liquid close to its melting point is 2.93 g/cm3.[20] The structure of molten alumina is temperature dependent and the fraction of 5- and 6-fold aluminium increases during cooling (and supercooling), at the expense of tetrahedral AlO4 units, approaching the local structural arrangements found in amorphous alumina.[21]

Production

[edit]Aluminium hydroxide minerals are the main component of bauxite, the principal ore of aluminium. A mixture of the minerals comprise bauxite ore, including gibbsite (Al(OH)3), boehmite (γ-AlO(OH)), and diaspore (α-AlO(OH)), along with impurities of iron oxides and hydroxides, quartz and clay minerals.[22] Bauxites are found in laterites. Bauxite is typically purified using the Bayer process:

- Al2O3 + H2O + NaOH → NaAl(OH)4

- Al(OH)3 + NaOH → NaAl(OH)4

Except for SiO2, the other components of bauxite do not dissolve in base. Upon filtering the basic mixture, Fe2O3 is removed. When the Bayer liquor is cooled, Al(OH)3 precipitates, leaving the silicates in solution.

- NaAl(OH)4 → NaOH + Al(OH)3

The solid Al(OH)3 Gibbsite is then calcined (heated to over 1100 °C) to give aluminium oxide:[7]

- 2 Al(OH)3 → Al2O3 + 3 H2O

The product aluminium oxide tends to be multi-phase, i.e., consisting of several phases of aluminium oxide rather than solely corundum.[17] The production process can therefore be optimized to produce a tailored product. The type of phases present affects, for example, the solubility and pore structure of the aluminium oxide product which, in turn, affects the cost of aluminium production and pollution control.[17]

Sintering Process

[edit]The Sintering Process is a high-temperature method primarily used when the Bayer Process is not suitable, especially for ores with high silica content or when a more controlled product morphology is required.[23] Firstly, Bauxite is mixed with additives like limestone and soda ash, then heating the mixture at high temperatures (1200 °C to 1500 °C) to form sodium aluminate and calcium silicate.[24] After sintering, the material is leached with water to dissolve the sodium aluminate, leaving behind impurities. Sodium aluminate is then precipitated from the solution and calcined at around 1000 °C to produce alumina.[25] This method is useful for the production of complex shapes and can be used to create porous or dense materials.[26]

Applications

[edit]Known as alpha alumina in materials science, and as alundum (in fused form) or aloxite[27] in mining and ceramic communities, aluminium oxide finds wide use. Annual global production of aluminium oxide in 2015 was approximately 115 million tonnes, over 90% of which was used in the manufacture of aluminium metal.[7] The major uses of speciality aluminium oxides are in refractories, ceramics, polishing and abrasive applications. Large tonnages of aluminium hydroxide, from which alumina is derived, are used in the manufacture of zeolites, coating titania pigments, and as a fire retardant/smoke suppressant.

Over 90% of aluminium oxide, termed smelter grade alumina (SGA), is consumed for the production of aluminium, usually by the Hall–Héroult process. The remainder, termed specialty alumina, is used in a wide variety of applications which take advantage of its inertness, temperature resistance and electrical resistance.[28]

Fillers

[edit]Being fairly chemically inert and white, aluminium oxide is a favored filler for plastics. Aluminium oxide is a common ingredient in sunscreen[29] and is often also present in cosmetics such as blush, lipstick, and nail polish.[30]

Glass

[edit]Many formulations of glass have aluminium oxide as an ingredient.[31] Aluminosilicate glass is a commonly used type of glass that often contains 5% to 10% alumina.

Catalysis

[edit]Aluminium oxide catalyses a variety of reactions that are useful industrially. In its largest scale application, aluminium oxide is the catalyst in the Claus process for converting hydrogen sulfide waste gases into elemental sulfur in refineries. It is also useful for dehydration of alcohols to alkenes.

Aluminium oxide serves as a catalyst support for many industrial catalysts, such as those used in hydrodesulfurization and some Ziegler–Natta polymerizations.

Gas purification

[edit]Aluminium oxide is widely used to remove water from gas streams.[32]

Abrasion

[edit]Aluminium oxide is used for its hardness and strength. Its naturally occurring form, corundum, is a 9 on the Mohs scale of mineral hardness (just below diamond). It is widely used as an abrasive, including as a much less expensive substitute for industrial diamond. Many types of sandpaper use aluminium oxide crystals. In addition, its low heat retention and low specific heat make it widely used in grinding operations, particularly cutoff tools. As the powdery abrasive mineral aloxite, it is a major component, along with silica, of the cue tip "chalk" used in billiards. Aluminium oxide powder is used in some CD/DVD polishing and scratch-repair kits. Its polishing qualities are also behind its use in toothpaste. It is also used in microdermabrasion, both in the machine process available through dermatologists and estheticians, and as a manual dermal abrasive used according to manufacturer directions.

Paint

[edit]Aluminium oxide flakes are used in paint for reflective decorative effects, such as in the automotive or cosmetic industries.[citation needed]

Biomedical Applications

[edit]Aluminium oxide is a representative of bioinert ceramics.[33] Due to its excellent biocompatibility, high strength, and wear resistance, alumina ceramics are used in medical applications to manufacture artificial bones and joints.[34] It is also used for manufacturing dental implants, joint replacements, and other medical devices.[35]

Composite fiber

[edit]Aluminium oxide has been used in a few experimental and commercial fiber materials for high-performance applications (e.g., Fiber FP, Nextel 610, Nextel 720).[36] Alumina nanofibers in particular have become a research field of interest.

Armor

[edit]Some body armors utilize alumina ceramic plates, usually in combination with aramid or UHMWPE backing to achieve effectiveness against most rifle threats. Alumina ceramic armor is readily available to most civilians in jurisdictions where it is legal, but is not considered military grade.[37] It is also used to produce bullet-proof alumina glass capable to withstand impact of .50 BMG calibre rounds.

Abrasion protection

[edit]Aluminium oxide can be grown as a coating on aluminium by anodizing or by plasma electrolytic oxidation (see the "Properties" above). Both the hardness and abrasion-resistant characteristics of the coating originate from the high strength of aluminium oxide, yet the porous coating layer produced with conventional direct current anodizing procedures is within a 60–70 Rockwell hardness C range[38] which is comparable only to hardened carbon steel alloys, but considerably inferior to the hardness of natural and synthetic corundum. Instead, with plasma electrolytic oxidation, the coating is porous only on the surface oxide layer while the lower oxide layers are much more compact than with standard DC anodizing procedures and present a higher crystallinity due to the oxide layers being remelted and densified to obtain α-Al2O3 clusters with much higher coating hardness values circa 2000 Vickers hardness.[citation needed]

Alumina is used to manufacture tiles which are attached inside pulverized fuel lines and flue gas ducting on coal fired power stations to protect high wear areas. They are not suitable for areas with high impact forces as these tiles are brittle and susceptible to breakage.

Electrical insulation

[edit]Aluminium oxide is an electrical insulator used as a substrate (silicon on sapphire) for integrated circuits,[39] but also as a tunnel barrier for the fabrication of superconducting devices such as single-electron transistors, superconducting quantum interference devices (SQUIDs) and superconducting qubits.[40][41]

For its application as an electrical insulator in integrated circuits, where the conformal growth of a thin film is a prerequisite and the preferred growth mode is atomic layer deposition, Al2O3 films can be prepared by the chemical exchange between trimethylaluminium (Al(CH3)3) and H2O:[42]

- 2 Al(CH3)3 + 3 H2O → Al2O3 + 6 CH4

H2O in the above reaction can be replaced by ozone (O3) as the active oxidant and the following reaction then takes place:[43][44]

- 2 Al(CH3)3 + O3 → Al2O3 + 3 C2H6

The Al2O3 films prepared using O3 show 10–100 times lower leakage current density compared with those prepared by H2O.

Aluminium oxide, being a dielectric with relatively large band gap, is used as an insulating barrier in capacitors.[45]

Other

[edit]In lighting, translucent aluminium oxide is used in some sodium vapor lamps.[46] Aluminium oxide is also used in preparation of coating suspensions in compact fluorescent lamps.

In chemistry laboratories, aluminium oxide is a medium for chromatography, available in basic (pH 9.5), acidic (pH 4.5 when in water) and neutral formulations. Additionally, small pieces of aluminium oxide are often used as boiling chips.

Health and medical applications include it as a material in hip replacements[7] and birth control pills.[47]

It is used as a scintillator[48] and dosimeter for radiation protection and therapy applications for its optically stimulated luminescence properties.[citation needed]

Insulation for high-temperature furnaces is often manufactured from aluminium oxide. Sometimes the insulation has varying percentages of silica depending on the temperature rating of the material. The insulation can be made in blanket, board, brick and loose fiber forms for various application requirements.

It is also used to make spark plug insulators.[49]

Using a plasma spray process and mixed with titania, it is coated onto the braking surface of some bicycle rims to provide abrasion and wear resistance.[citation needed]

Most ceramic eyes on fishing rods are circular rings made from aluminium oxide.[citation needed]

In its finest powdered (white) form, called Diamantine, aluminium oxide is used as a superior polishing abrasive in watchmaking and clockmaking.[50]

Aluminium oxide is also used in the coating of stanchions in the motorcross and mountainbike industry. This coating is combined with molybdenumdisulfate to provide long term lubrication of the surface.[51]

See also

[edit]- Aluminium oxide nanoparticle

- Bauxite tailings

- Beta-alumina solid electrolyte, a fast ion conductor

- Charged Aerosol Release Experiment (CARE)

- List of alumina refineries

- Micro-pulling-down

- Transparent alumina

References

[edit]- ^ "Aluminum oxide_msds".

- ^ Jump up to: a b Material Properties Data: Alumina (Aluminum Oxide) Archived 2010-04-01 at the Wayback Machine. Makeitfrom.com. Retrieved on 2013-04-17.

- ^ Patnaik, P. (2002). Handbook of Inorganic Chemicals. McGraw-Hill. ISBN 978-0-07-049439-8.

- ^ Raymond C. Rowe; Paul J. Sheskey; Marian E. Quinn (2009). "Adipic acid". Handbook of Pharmaceutical Excipients. Pharmaceutical Press. pp. 11–12. ISBN 978-0-85369-792-3.

- ^ Jump up to: a b Zumdahl, Steven S. (2009). Chemical Principles 6th Ed. Houghton Mifflin Company. ISBN 978-0-618-94690-7.

- ^ Jump up to: a b NIOSH Pocket Guide to Chemical Hazards. "#0021". National Institute for Occupational Safety and Health (NIOSH).

- ^ Jump up to: a b c d e "Alumina (Aluminium Oxide) – The Different Types of Commercially Available Grades". The A to Z of Materials. 3 May 2002. Archived from the original on 10 October 2007. Retrieved 27 October 2007.

- ^ Elam, J. W. (October 2010). Atomic Layer Deposition Applications 6. The Electrochemical Society. ISBN 9781566778213.

- ^ "Deltalumite".

- ^ "List of Minerals". 21 March 2011.

- ^ Gitzen, Walter (1970). Alumina as a Ceramic Material. Wiley.

- ^ Dorre, Erhard; Hubner, Heinz (1984). Alumina, Processing, Properties, and Applications. Berlin; New York: Springer-Verlag. p. 344.

- ^ Ruys, Andrew J. (2019). Alumina Ceramics: Biomedical and Industrial Applications. Duxford, UK: Elsevier. p. 558. ISBN 978-0-08-102442-3.

- ^ Campbell, Timothy; Kalia, Rajiv; Nakano, Aiichiro; Vashishta, Priya; Ogata, Shuji; Rodgers, Stephen (1999). "Dynamics of Oxidation of Aluminium Nanoclusters using Variable Charge Molecular-Dynamics Simulations on Parallel Computers" (PDF). Physical Review Letters. 82 (24): 4866. Bibcode:1999PhRvL..82.4866C. doi:10.1103/PhysRevLett.82.4866. Archived (PDF) from the original on 2010-07-01.

- ^ "EPCRA Section 313 Chemical List For Reporting Year 2006" (PDF). US EPA. Archived from the original (PDF) on 2008-05-22. Retrieved 2008-09-30.

- ^ Jump up to: a b I. Levin; D. Brandon (1999). "Metastable Alumina Polymorphs: Crystal Structures and Transition Sequences". Journal of the American Ceramic Society. 81 (8): 1995–2012. doi:10.1111/j.1151-2916.1998.tb02581.x.

- ^ Jump up to: a b c Paglia, G. (2004). "Determination of the Structure of γ-Alumina using Empirical and First Principles Calculations Combined with Supporting Experiments" (free download). Curtin University of Technology, Perth. Retrieved 2009-05-05.

- ^ Wiberg, E.; Holleman, A. F. (2001). Inorganic Chemistry. Elsevier. ISBN 978-0-12-352651-9.

- ^ Jump up to: a b Skinner, L.B.; et al. (2013). "Joint diffraction and modeling approach to the structure of liquid alumina". Phys. Rev. B. 87 (2): 024201. Bibcode:2013PhRvB..87b4201S. doi:10.1103/PhysRevB.87.024201.

- ^ Paradis, P.-F.; et al. (2004). "Non-Contact Thermophysical Property Measurements of Liquid and Undercooled Alumina". Jpn. J. Appl. Phys. 43 (4): 1496–1500. Bibcode:2004JaJAP..43.1496P. doi:10.1143/JJAP.43.1496. S2CID 250779901.

- ^ Shi, C; Alderman, O L G; Berman, D; Du, J; Neuefeind, J; Tamalonis, A; Weber, R; You, J; Benmore, C J (2019). "The structure of amorphous and deeply supercooled liquid alumina". Frontiers in Materials. 6 (38): 38. Bibcode:2019FrMat...6...38S. doi:10.3389/fmats.2019.00038.

- ^ "Bauxite and Alumina Statistics and Information". USGS. Archived from the original on 6 May 2009. Retrieved 2009-05-05.

- ^ Alton T. Tabereaux, Ray D. Peterson (2014). "Chapter 2.5 - Aluminum Production". In Seshadri Seetharaman (ed.). Treatise on Process Metallurgy. Elsevier. pp. 839–917. ISBN 9780080969886.

- ^ Bordboland, Reza; Azizi, Asghar; Khani, Mohammad (2024). "Extracting Alumina from a Low-grade (Shale) Bauxite Ore using a Sintering Process with Lime-soda followed by Alkali Leaching". Journal of Mining and Environment. 15 (3): 1131–1148. doi:10.22044/jme.2024.13905.2588.

- ^ Sun, Yue; Pan, Aifang (2023). "Extraction of alumina and silica from high-silica bauxite by sintering with sodium carbonate followed by two-step leaching with water and sulfuric acid". RSC Advances. 13: 23254–23266.

- ^ "Several Production Methods of Alumina and Their Advantages". Precise Ceramics. Apr 3, 2024. Retrieved Aug 19, 2024.

- ^ "Aloxite". ChemIndustry.com database. Archived from the original on 25 June 2007. Retrieved 24 February 2007.

- ^ Evans, K. A. (1993). "Properties and uses of aluminium oxides and aluminium hydroxides". In Downs, A. J. (ed.). The Chemistry of Aluminium, Indium and Gallium. Blackie Academic. ISBN 978-0751401035.

- ^ "Alumina". INCI Decoder. Archived from the original on 5 February 2023. Retrieved 20 June 2023.

- ^ "Alumina (Ingredient Explained + Products)". SkinSort. Archived from the original on 15 October 2023. Retrieved 15 October 2023.

- ^ Akers, Michael J. (2016-04-19). Sterile Drug Products: Formulation, Packaging, Manufacturing and Quality. CRC Press. ISBN 9781420020564.

- ^ Hudson, L. Keith; Misra, Chanakya; Perrotta, Anthony J.; Wefers, Karl and Williams, F. S. (2002) "Aluminum Oxide" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_557.

- ^ Ishikawa, K.; Matsuya, S. (2003). Comprehensive Structural Integrity. Vol. 9. Elsevier Science. pp. 169–214. ISBN 978-0-08-043749-1. Retrieved May 27, 2024.

- ^ "Alumina (Al2O3), Aluminum Oxide". Precise Ceramic. Retrieved May 27, 2024.

- ^ "Metals and Minerals in Medical Implants". USGS. Retrieved May 27, 2024.

- ^ Mallick, PK (2008). Волокон-армированные композиты Материалы, производство и дизайн (3-е изд., [Расширенное и обоснованное ред.] Изд.). Boca Raton, FL: CRC Press. с. гл.2.1.7. ISBN 978-0-8493-4205-9 .

- ^ «Баллистическое сопротивление бронежик» (PDF) . Министерство юстиции США . Nij . Получено 31 августа 2018 года .

- ^ Осборн, Джозеф Х. (2014). «Понимание и определение анодирования: что должен знать производителю» . OMW Corporation . Архивировано с оригинала 2016-11-20 . Получено 2018-06-02 .

- ^ Баттерфилд, Эндрю; Шимански, Джон (2018). Словарь электроники и электротехники . Издательство Оксфордского университета. ISBN 9780198725725 Полем Получено 7 сентября 2024 года .

- ^ Росс, Лиза (31 января 2024 г.). "Почему оксид алюминия используется в инструментах?" Полем Усовершенствованные керамические материалы . Получено 7 сентября 2024 года .

- ^ Дживандара, Тамараси (2 сентября 2021 г.). «Материалы для сверхпроводящих кубитов» . Физический Получено 7 сентября 2024 года .

- ^ Хигаши Г.С., Флеминг (1989). «Последовательная поверхностная химическая реакция ограниченный рост высококачественных диэлектриков AL 2 O 3 ». Приложение Физический Летал 55 (19): 1963–65. Bibcode : 1989Apphl..55.1963H . doi : 10.1063/1,102337 .

- ^ Ким Дж. Б.; Kwon Dr; Чакрабарти К; Ли Чонгму; О, Кай; Ли Дж. Х. (2002). «Улучшение диэлектрического поведения AL 2 O 3 с использованием озона в качестве окислителя для метода осаждения атомного слоя». J. Appl. Физический 92 (11): 6739–42. Bibcode : 2002Jap .... 92.6739K . doi : 10.1063/1.1515951 .

- ^ Ким, Джебум; Чакрабарти, Кунтал; Ли, Джинхо; О, Ки-Янг; Lee, Chongmu (2003). «Влияние озона в качестве источника кислорода на свойства тонких пленок Al 2 O 3, приготовленных при осаждении атомного слоя». Mater Chem Phys . 78 (3): 733–38. doi : 10.1016/s0254-0584 (02) 00375-9 .

- ^ Belkin, A.; Bezryadin, A.; Hendren, L.; Hubler, A. (20 апреля 2017 г.). «Восстановление нанокапоциторов глинозема после высокого расщепления напряжения» . Научные отчеты . 7 (1): 932. Bibcode : 2017natsr ... 7..932b . doi : 10.1038/s41598-017-01007-9 . PMC 5430567 . PMID 28428625 .

- ^ «Ге -инновационная временная шкала 1957–1970» . Архивировано из оригинала 16 февраля 2009 года . Получено 2009-01-12 .

- ^ «Dailemed - Junel Fe 1/20 - ацетат нориэтиндрона и этинилэстрадиола, а также железной фумарат» . Dailemed.nlm.nih.gov . Архивировано из оригинала 2017-03-13 . Получено 2017-03-13 .

- ^ VB Mikhailik, H. Kraus (2005). «Низкотемпературная спектроскопическая и сцинтилляционная характеристика TI-легированного AL 2 O 3 ». Нукле Инструмент Физический Резерв А 546 (3): 523–534. Bibcode : 2005nimpa.546..523m . doi : 10.1016/j.nima.2005.02.033 .

- ^ Фарндон, Джон (2001). Алюминий . Маршалл Кавендиш. п. 19 ISBN 9780761409472 Полем

Оксид алюминия также используется для изготовления изоляторов зажигания зажигания.

- ^ Чарльз, Дональд (1969). СМОТРЕТЬ Практическое ремонт Nag Press Ltd. п. 164. ISBN 0719800307 .

- ^ «Кашима пальто - продукты / услуги | Анодиз следующего поколения с легким весом, высокой смазкой и превосходной стойкостью к износу. Ответ - кашима -пальто Мияки» .

Внешние ссылки

[ редактировать ]